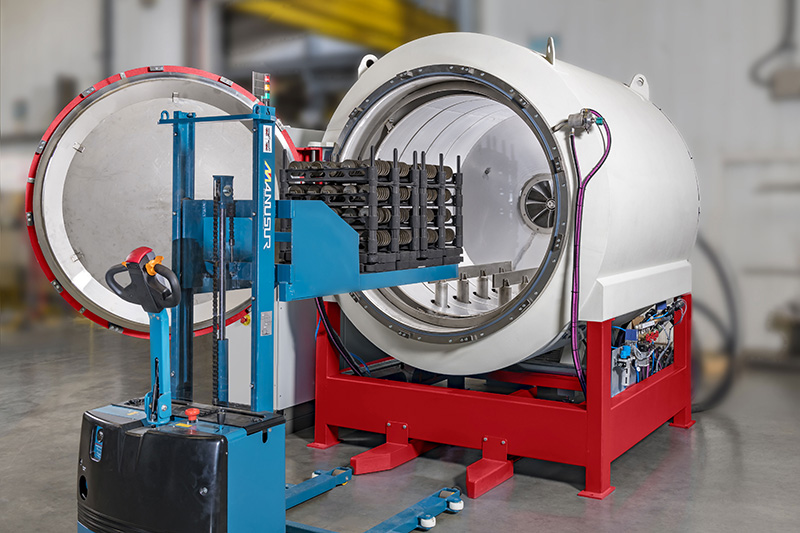

HOT WALL FORCED CONVECTION FURNACES FOR NITRIDING APPLICATIONS – VESUVE RANGE

The treatment of nitriding is carried out by means of a furnace with air convection forced with a pressure of work ranging between 20 to 50 mbar relative and of a mixture of active gas. This technology makes it possible to increase the gaseous exchange on the surface of the parts. Moreover, the quality of the treatment will be ensured by the fact that the load is to place in a tight heat-resisting steel muffle. The active species N result from chemical reactions and the dissociation of ammonia NH3 at the temperature of treatment (500 to 600°C).

OUR NITRIDING FURNACES ADVANTAGES

- Excellent quality and repeatability of treatments

- Shortened cooling time

- Integration in a flexible line

- User friendly interface and process management

NITRIDING FURNACES CARACTERISTICS

The VESUVE furnace range is a Horizontal loading standard equipped with a door articulated on axis of rotation. The standard installation comprises

- A casing with walls heat isolated thermally from the heaters

- A muffle

- A door with reinforced thermal isolation

- A turbine of convection

- A cabinet of remote control

- A pumping installation ensuring the cycle of purging

- A gas process panel – (NH3-N2) – CO2 – H2S

- A water circuit

- A wing exchanger for accelerated cooling

- Gas exhaust burner

PROCESSES :

- Nitriding

- Nitrocarburizing

- Oxynitriding

- Post-oxidation

- Tempering